While electric vehicles dominate headlines, internal combustion engine (ICE) technology continues to evolve at a remarkable pace. Despite the push toward electrification, traditional car engines remain the backbone of global automotive transportation, powering millions of vehicles across diverse applications. The latest innovations in ICE technology are proving that traditional engines still have significant potential for improvement, efficiency gains, and environmental benefits.

In India, where fuel efficiency and cost-effectiveness remain paramount concerns for consumers, recent advances in petrol cars and diesel engines are reshaping the automotive landscape. Modern ICE technology developments are addressing critical challenges including improved fuel economy, reduced emissions, and enhanced performance – all while maintaining the reliability and affordability that Indian consumers demand.

The global automotive industry continues to invest heavily in ICE innovations, recognizing that internal combustion engines are the standard, and typically the only, power option in hundreds of applications serving every corner of the globe. These investments are yielding breakthrough technologies that promise to extend the relevance of traditional engines well into the future.

The Current State of ICE Technology in 2025

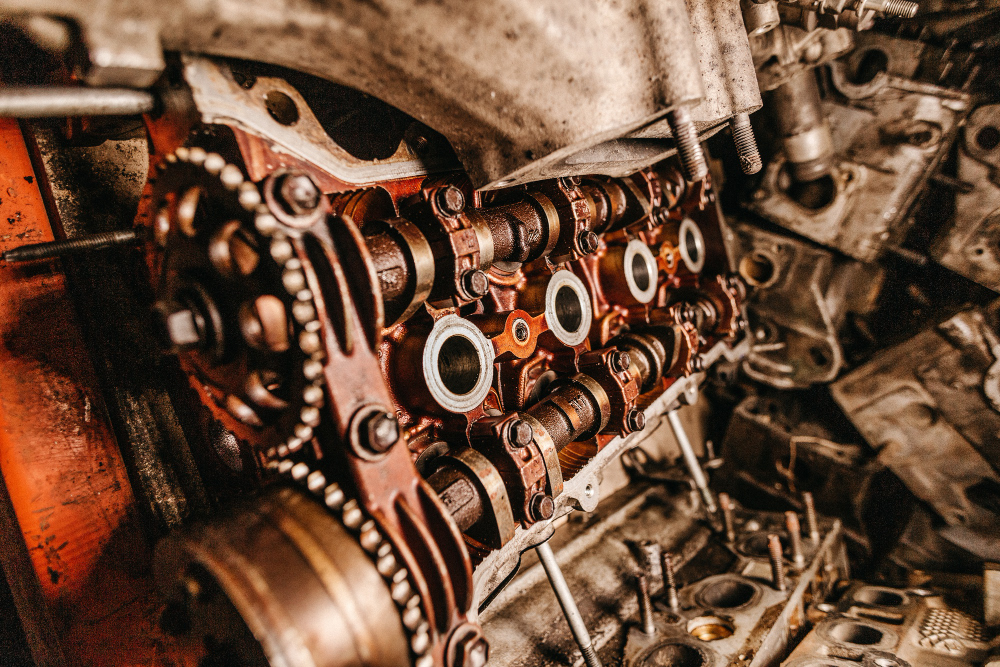

Today’s internal combustion engines represent the pinnacle of over a century of automotive engineering evolution. Modern engines achieve unprecedented levels of efficiency through sophisticated design improvements, advanced materials, and cutting-edge control systems. The integration of digital technologies with mechanical precision has created engines that would have been unimaginable just a decade ago.

Contemporary ICE technology incorporates multiple innovations working in harmony. Variable valve timing systems optimize engine breathing across different operating conditions. Direct injection systems provide precise fuel delivery, while turbocharging and supercharging technologies extract maximum power from smaller displacement engines. These technologies work together to deliver both performance and efficiency.

Advanced engine management systems use artificial intelligence and machine learning algorithms to optimize combustion in real-time. These systems continuously monitor hundreds of parameters and adjust engine operation thousands of times per second. The result is engines that adapt to driving conditions, fuel quality, and environmental factors to maintain optimal performance.

The materials science revolution has enabled engineers to build engines with components that operate at higher temperatures and pressures while maintaining durability. Advanced alloys, ceramic composites, and specialized coatings allow engines to achieve efficiency levels that were previously impossible while extending service life.

Revolutionary Efficiency Improvements in Modern Engines

Engine efficiency has reached new heights through innovative combustion strategies and thermal management systems. Modern engines achieve thermal efficiencies exceeding 40%, compared to around 25% for engines from previous generations. These improvements translate directly into better fuel economy and reduced emissions without sacrificing performance.

Variable compression ratio technology represents one of the most significant recent breakthroughs. These systems can adjust the compression ratio based on operating conditions, providing high compression for efficiency during light loads and lower compression to prevent knock during high-power operation. This technology delivers the best of both worlds – efficiency and performance.

Lean-burn combustion strategies enable engines to operate with air-fuel ratios that significantly exceed stoichiometric values. These systems use precise fuel injection timing and advanced ignition systems to maintain stable combustion while using less fuel. The result is improved fuel economy with reduced carbon dioxide emissions.

Thermal barrier coatings and advanced cooling systems help engines operate at higher temperatures while maintaining component integrity. Higher operating temperatures improve thermodynamic efficiency and reduce heat losses. These systems also enable faster warm-up times, reducing cold-start emissions and improving fuel economy during short trips.

Advanced Fuel Injection and Combustion Technologies

Modern fuel injection systems represent a quantum leap from traditional port fuel injection. Direct injection systems place fuel injectors directly in the combustion chamber, enabling precise control of fuel timing, quantity, and spray patterns. This precision allows engineers to optimize combustion for different operating conditions.

Multi-injection strategies use multiple fuel injection events during each combustion cycle. Pilot injections prepare the combustion chamber, main injections provide primary power, and post-injections can assist with emissions control. This approach enables cleaner combustion with improved efficiency and reduced noise.

High-pressure fuel systems operating at pressures exceeding 2,000 bar enable extremely fine fuel atomization. Better atomization improves mixing with air and promotes more complete combustion. These systems work in conjunction with advanced injector designs that can deliver precise fuel quantities with microsecond timing accuracy.

Combustion chamber design has evolved to promote turbulence and improve mixing while minimizing heat losses. Sophisticated computer modeling helps engineers optimize chamber shapes, valve layouts, and piston designs to create ideal conditions for efficient combustion. These improvements reduce emissions while improving fuel economy.

Turbocharging and Supercharging Innovations

Forced induction technology has revolutionized engine design by enabling smaller engines to produce power levels traditionally associated with much larger engines. Modern turbocharging systems use advanced materials and precise manufacturing to achieve impressive efficiency gains while maintaining durability.

Variable geometry turbochargers adjust their internal geometry based on engine operating conditions. These systems provide strong low-end torque while avoiding over-boost at high engine speeds. The result is improved drivability across the entire engine speed range with better fuel economy.

Electric turbocharging represents the latest evolution in forced induction technology. These systems use electric motors to eliminate turbo lag while providing precise boost control. Electric assistance can also help reduce emissions during transient conditions when traditional turbochargers might not provide optimal performance.

Twin-scroll and twin-turbo configurations optimize forced induction for different engine characteristics. Twin-scroll systems separate exhaust pulses to improve turbine efficiency, while twin-turbo systems can use different sized turbochargers optimized for different engine speed ranges. These configurations provide both performance and efficiency benefits.

Engine Efficiency Improvements in the Indian Context

In India, where fuel costs represent a significant portion of vehicle operating expenses, engine efficiency improvements have particular importance. Diesel cars have higher fuel efficiency (20%-25% more) than petrol cars, making them attractive for high-mileage drivers despite higher purchase prices.

Indian manufacturers have developed engines specifically optimized for local driving conditions and fuel quality. These engines incorporate robust designs that can handle varying fuel quality while maintaining efficiency. Special attention to low-end torque characteristics ensures good performance in stop-and-go traffic conditions common in Indian cities.

Since 2014, India imposed passenger vehicle fuel-efficiency standards. Once implemented in 2015, these standards mandated efficiency targets for new cars at the equivalent of 130 gCO2/km in 2017 and 113 gCO2/km in 2022. These regulations have driven significant innovation in engine technology among manufacturers selling in the Indian market.

The Indian automotive market has seen remarkable improvements in engine efficiency across all segments. Diesel vehicle tends to have a fuel efficiency that’s 25-30% higher than that of petrol vehicles, making them particularly attractive for commercial applications and high-mileage personal use.

Alternative Fuels and ICE Technology Adaptation

The future of ICE technology increasingly involves adaptation to alternative fuels that can reduce environmental impact while maintaining the advantages of internal combustion engines. Upcoming changes range from detailed improvements to mechanical design or better emission systems that free the engine to run more efficiently, to radical architectural and combustion system changes. These will allow the use of very different, greener fuels that are at least 85% lower in CO2.

Hydrogen internal combustion engines represent a promising pathway for zero-emission ICE operation. These engines can use existing manufacturing infrastructure while providing the quick refueling and long-range advantages of traditional engines. Hydrogen engines require specialized combustion chamber designs and injection systems but maintain the fundamental operating principles of traditional ICE technology.

Biofuel compatibility has become increasingly important as sustainable fuel sources become more available. Modern engines incorporate materials and designs that can handle ethanol blends, biodiesel, and other renewable fuels without performance penalties. Flex-fuel capabilities allow engines to automatically adjust to different fuel compositions.

Synthetic fuels produced from renewable energy sources offer another pathway for sustainable ICE operation. These fuels can be chemically identical to traditional petroleum fuels while providing carbon-neutral operation when produced using renewable energy. ICE technology adaptations for synthetic fuels focus on optimizing combustion characteristics and emissions control systems.

Emissions Control and Environmental Innovations

Modern emissions control systems represent sophisticated combinations of catalytic converters, particulate filters, and exhaust gas recirculation systems. These technologies work together to reduce harmful emissions while maintaining engine performance and efficiency. Advanced control systems optimize emissions equipment operation based on real-time conditions.

Selective catalytic reduction (SCR) systems for diesel engines use urea injection to reduce nitrogen oxide emissions. These systems can achieve emission reductions exceeding 90% while actually improving fuel economy in some operating conditions. The integration of SCR with other emissions control technologies provides comprehensive emission reduction.

Gasoline particulate filters are becoming increasingly common as engines adopt direct injection technology. These filters capture particulate matter that can form during certain operating conditions. Advanced regeneration strategies ensure these filters maintain effectiveness while minimizing impact on fuel economy.

Real-time emissions monitoring systems use sophisticated sensors to continuously track emission levels and adjust engine operation accordingly. These systems can detect degradation in emissions control components and adapt engine operation to maintain compliance while alerting drivers to required maintenance.

Revolutionary Engine Design Concepts

The INNengine promises to revolutionize ICE technology with rotary, opposed pistons, representing one of several radical design approaches being explored to improve ICE efficiency and performance. These innovative designs challenge conventional engine architecture while maintaining the fundamental advantages of internal combustion.

Opposed-piston engines eliminate traditional cylinder heads while using two pistons per cylinder. This design reduces heat losses and mechanical complexity while potentially improving efficiency. Modern opposed-piston designs incorporate advanced materials and precision manufacturing to achieve impressive performance characteristics.

Rotary engine technology continues to evolve with modern materials and manufacturing techniques. New rotary designs address traditional challenges including seal durability and emissions control while maintaining the compact size and smooth operation advantages of rotary engines. These engines show particular promise for range-extender applications.

Free-piston engines represent another radical departure from conventional designs. These engines eliminate traditional crankshafts and connecting rods, instead using linear generators to capture energy directly from piston motion. This approach can potentially achieve higher efficiency while reducing mechanical complexity.

Digital Integration and Smart Engine Technologies

Modern engines incorporate sophisticated digital control systems that continuously optimize performance based on real-time conditions. These systems process inputs from dozens of sensors to make thousands of adjustments per second. Machine learning algorithms enable engines to adapt to individual driving patterns and optimize performance accordingly.

Predictive maintenance systems use sensor data and artificial intelligence to predict component wear and optimize maintenance schedules. These systems can identify potential problems before they cause failures, reducing maintenance costs and improving reliability. Integration with vehicle telematics systems enables remote monitoring and diagnostics.

Over-the-air updates allow manufacturers to continuously improve engine performance and efficiency after vehicles are sold. These updates can optimize engine maps, adjust emissions control strategies, and even add new features. This capability extends the useful life of engines while improving performance and efficiency over time.

Connected engine systems can communicate with infrastructure and other vehicles to optimize performance. These systems can adjust operation based on traffic conditions, weather, and road topology to maximize efficiency. Integration with navigation systems enables predictive optimization based on planned routes.

Manufacturing and Materials Innovations

Advanced manufacturing techniques enable the production of engine components with previously impossible precision and complexity. 3D printing technology allows the creation of intricate cooling passages and complex geometries that improve performance while reducing weight. These techniques also enable rapid prototyping and customization.

Additive manufacturing is revolutionizing engine component production. Complex internal cooling passages, integrated sensors, and optimized shapes can be created in single pieces rather than assembled from multiple components. This approach reduces manufacturing costs while improving performance and reliability.

Lightweight materials including advanced aluminum alloys, magnesium, and carbon fiber composites are reducing engine weight while maintaining strength. Weight reduction improves vehicle efficiency and performance while reducing emissions. These materials often require specialized manufacturing techniques and joining methods.

Surface treatments and coatings provide enhanced durability and performance characteristics. Diamond-like carbon coatings reduce friction and wear, while thermal barrier coatings enable higher operating temperatures. These treatments can significantly extend component life while improving efficiency.

The Future of ICE Technology in India

India Diesel Engine market is expected to reach US$ 9.10 billion in 2024 to US$ 13.20 billion by 2033, with a CAGR of 4.22% from 2025 to 2033, indicating continued strong demand for diesel engine technology in the Indian market. This growth reflects the ongoing importance of ICE technology in commercial and personal transportation applications.

Indian manufacturers are investing heavily in ICE technology development to meet both domestic and export market requirements. Focus areas include improved fuel efficiency, reduced emissions, and enhanced durability to meet the diverse operating conditions found in Indian markets. These developments position Indian manufacturers as global leaders in cost-effective ICE technology.

The regulatory environment in India continues to drive innovation in ICE technology. Stricter emission standards and fuel efficiency requirements are pushing manufacturers to develop more advanced engines. These regulations create opportunities for innovative technologies while ensuring environmental benefits.

Alternative fuel adaptation is becoming increasingly important in the Indian market. Ethanol blending requirements and CNG availability are driving engine development efforts. Manufacturers are developing engines optimized for these alternative fuels while maintaining the cost-effectiveness required for the Indian market.

Economic Impact and Market Dynamics

The ICE technology sector continues to generate significant economic activity and employment opportunities. Traditional automotive supply chains support millions of jobs in manufacturing, research, and development activities. Continued innovation in ICE technology sustains these economic benefits while providing pathways for technological advancement.

Investment in ICE technology development remains substantial as manufacturers seek to improve efficiency and reduce emissions. These investments support advanced manufacturing capabilities, research facilities, and skilled workforce development. The economic multiplier effects of these investments benefit entire regions and countries.

Export opportunities for advanced ICE technology provide significant economic benefits for countries with strong automotive industries. Indian manufacturers are increasingly exporting engines and engine technology to global markets, generating foreign exchange and supporting domestic employment.

The aftermarket for ICE technology including maintenance, repair, and performance upgrades represents a substantial economic sector. Continued ICE technology development ensures the sustainability of these economic activities while providing opportunities for innovation and growth.

Challenges and Future Directions

Despite impressive technological advances, ICE technology faces significant challenges including increasingly stringent emission regulations and competition from electric vehicles. Meeting these challenges requires continued innovation in engine design, emissions control, and alternative fuel adaptation. The industry must balance performance, efficiency, cost, and environmental impact.

Regulatory compliance represents an ongoing challenge as emission standards become more demanding. Future regulations may require even more sophisticated emissions control systems and alternative fuel compatibility. Manufacturers must invest in research and development to stay ahead of regulatory requirements.

Competition from electric vehicles is driving ICE technology development toward higher efficiency and lower emissions. While electric vehicles offer advantages in certain applications, ICE technology continues to provide benefits including quick refueling, long range, and lower infrastructure requirements. Continued innovation helps maintain these competitive advantages.

Cost pressures from consumers and regulatory requirements create challenges for ICE technology development. Advanced technologies must be cost-effective to achieve market acceptance. Manufacturers must balance technological advancement with affordability, particularly in price-sensitive markets like India.

FAQs

What are the latest innovations in ICE technology that improve fuel efficiency?

Recent innovations include variable compression ratio systems, advanced direct injection, lean-burn combustion strategies, and sophisticated engine management systems using AI. These technologies can improve fuel efficiency by 20-30% compared to previous generation engines while maintaining performance.

How do modern petrol cars compare to diesel engines in terms of efficiency in India?

Diesel engines typically offer 20-25% better fuel efficiency than petrol engines, making them attractive for high-mileage drivers despite higher purchase costs. However, modern petrol engines with turbocharging and direct injection have significantly narrowed this efficiency gap.

What role do alternative fuels play in modern ICE technology?

Alternative fuels including ethanol blends, biodiesel, hydrogen, and synthetic fuels offer pathways for reducing ICE emissions. Modern engines are being designed with flex-fuel capabilities and can adapt to different fuel compositions while maintaining performance and efficiency.

How are emissions being reduced in modern ICE engines?

Advanced emissions control systems including selective catalytic reduction, particulate filters, and sophisticated exhaust gas recirculation reduce harmful emissions by over 90%. Real-time monitoring and adaptive control systems ensure optimal emissions performance across all operating conditions.

What are the key advantages of ICE technology over electric vehicles?

ICE vehicles offer quick refueling times, long range, lower infrastructure requirements, and proven reliability. They perform well in extreme weather conditions and can utilize existing fuel distribution networks. For many applications, ICE technology remains more practical and cost-effective.

How is the Indian automotive market adapting to new ICE technologies?

Indian manufacturers are developing engines optimized for local conditions while meeting international efficiency standards. Focus areas include improved fuel efficiency, alternative fuel compatibility, and robust designs that handle varying fuel quality and operating conditions.

What manufacturing innovations are improving ICE engine production?

Advanced manufacturing techniques including 3D printing, precision machining, and additive manufacturing enable complex component geometries and improved performance. These techniques reduce costs while enabling customization and rapid prototyping of new designs.

How do digital technologies enhance modern ICE engines?

Digital integration enables real-time optimization, predictive maintenance, over-the-air updates, and connected vehicle capabilities. AI and machine learning algorithms continuously adapt engine performance to driving conditions and individual usage patterns.

What is the future outlook for ICE technology development?

ICE technology will continue evolving with focus on alternative fuels, higher efficiency, and lower emissions. While electric vehicles will grow in certain segments, ICE technology will remain important for many applications requiring long range, quick refueling, and cost-effectiveness.

How do turbocharging innovations improve engine performance?

Modern turbocharging systems including variable geometry turbos and electric assistance eliminate lag while providing precise boost control. These systems enable smaller engines to produce more power while improving fuel efficiency and reducing emissions.

The continued evolution of internal combustion engine technology demonstrates that traditional powertrains still have significant potential for improvement. Through innovative design, advanced materials, and digital integration, modern ICE technology is achieving unprecedented levels of efficiency and environmental performance. As the automotive industry navigates the transition to electrification, these innovations ensure that internal combustion engines remain relevant and competitive in the evolving transportation landscape. The combination of proven reliability, ongoing innovation, and economic advantages positions ICE technology as a continuing force in global automotive markets, particularly in regions like India where cost-effectiveness and fuel efficiency remain paramount considerations.